Adapt Quick-Fit® Ducting to Existing Flanged Ductwork

Nordfab® Quick-Fit® (QF) ducting is well-known for versatility and ease of installation. These innovative ducting solutions can be seamlessly integrated with existing flanged duct systems using an Angle Flange Adapter. The ability to integrate Nordfab® ensures that businesses can upgrade their ductwork systems without the need for a complete overhaul, saving both time and resources.

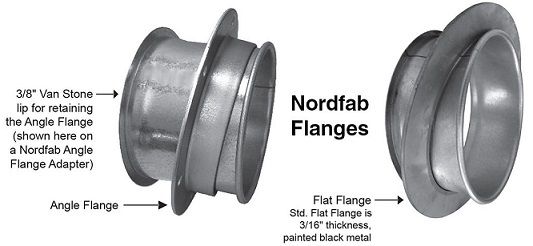

Norfab Angle Flange Adapters are engineered for optimal performance and compatibility. They feature a QF rolled edge on one end, which allows for quick and secure connections with other QF components. On the other end, a standard angle ring provides a robust interface with traditional flanged systems. This dual-ended design makes these adapters the perfect bridge between modern QF systems and legacy duct installations.

For applications requiring specific configurations, we also offer Flat Flange ends. These can be customized to meet your unique hole pattern requirements, ensuring a perfect fit for any specialized ducting setup. This flexibility allows for tailored solutions that address the needs of various industries, from manufacturing to food processing, and more.

Nordfab® Duct Pipe in diameters larger than 24"

• QF ducting is available in diameters of up to 24"

• For larger duct requirements, we carry Nordfab® flanged duct pipe in diameters of up to 40"

• Flanged duct pipe is constructed from sheet blanks that are 78.75" long and rolled with a longitudinal lock-form seam.

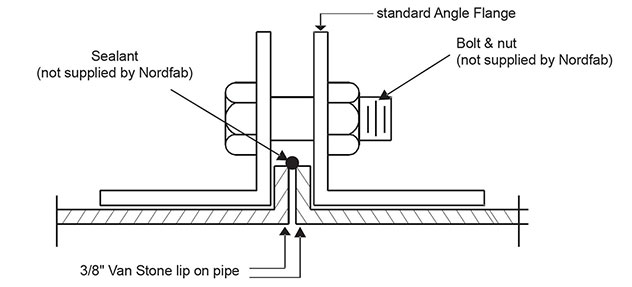

As seen above, an industry standard angle flange made from angle bar stock rolled on edge is placed on the end of the duct and secured using a Van Stone lip connection.

• The loose flange allows easy matchup to holes on existing flanges.

• The connection of two flanged pipes is illustrated in the example below.

Expanding on the larger diameter options:

Our flanged duct pipes in sizes 26" to 40" are designed to handle high-volume air flow requirements in industrial settings. These larger pipes are ideal for applications such as dust collection in woodworking facilities, fume extraction in chemical plants, or ventilation in large manufacturing spaces.

The construction of these larger ducts prioritizes both strength and efficiency. The longitudinal lock-form seam provides excellent structural integrity, while the Van Stone lip connection ensures a secure and leak-resistant joint between the pipe and the flange. This design also allows for easy disassembly and cleaning, which is crucial for maintaining optimal system performance and complying with safety regulations.

For systems requiring a mix of pipe sizes, Nordfab® offers reducers and expanders that can smoothly transition between different diameters. This allows for the creation of complex ducting systems that can efficiently manage varying air flow requirements across different sections of a facility.

When installing large diameter ducting, it's important to consider factors such as support structures, pressure drop calculations, and system balancing. Our team of experts is available to provide guidance on system design and installation to ensure your large-scale ducting solution meets all performance and safety standards.

You may also like:

• 8 Reasons to Use Nordfab® Ducting

• Ducting Parts and Supplies

• Dust Collector Duct Design