Oil Mist Collector Ducting

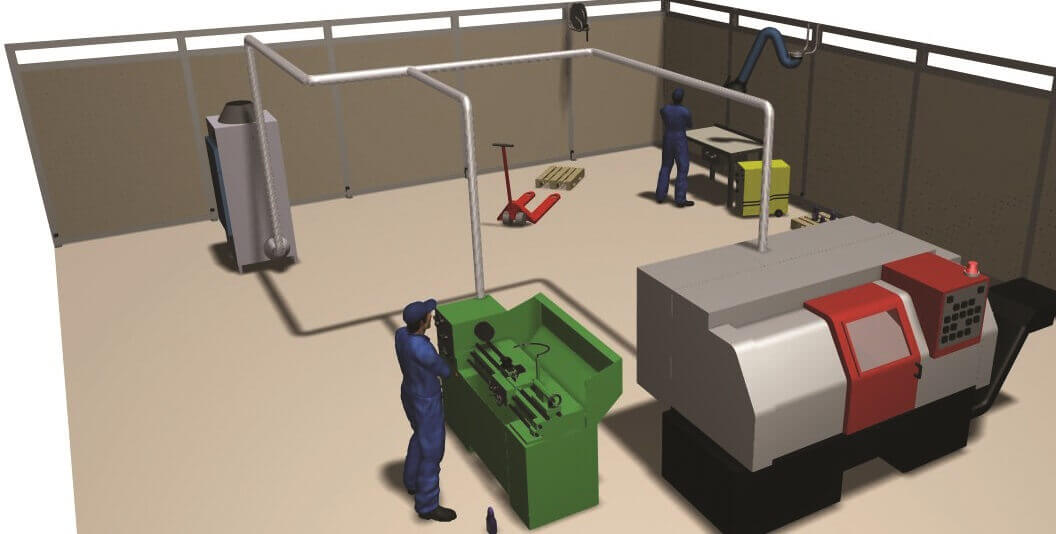

Oil mists and cutting fluid vapors generated from machining operations and metalworking processes present unique challenges that require specialized sealed duct systems. These airborne contaminants pose health risks to workers and can cause equipment damage through condensation, corrosion, and contamination of electronic components.

Oil mists from general industrial processes, cutting fluid vapors from machining operations, and coolant mists from automotive manufacturing all produce fine aerosols that become airborne during production. When these contaminants condense on surfaces, they create slippery conditions, leading to workplace accidents and can cause rust buildup or mold accumulation.

Condensation control is critical in oil mist applications to prevent leakage and drippage on equipment. When cold air meets warm air, water and mist accumulate on pipes, causing them to drip on circuitry and electronic components. The heat generated by machining tools combines with cutting fluids to create oil mist that must be effectively collected to prevent health and safety risks.

Oil Mist Ducting Solutions

Collection systems for oil mists require completely sealed ductwork to prevent contaminated air from escaping and to manage condensation effectively. The captured airstream moves oil-laden air into specialized collectors that separate solid materials from the air, improving air quality.

Nordfab ducting offers specialized sealed systems for oil mist and cutting fluid collection across machine shops, automotive plants, and metal fabrication facilities.

This sealed system approach provides excellent leak protection compared to traditional lock-form seams. The combination efficiently collects and separates cutting fluid mist, while removing moisture and preventing accumulation on machinery, creating safer working environments and protecting valuable equipment from contamination damage.

Request A Quote:

If you would like to request a quote for a ducting system, or to get more information about our products, please email us or use the form on our Contact Us page for support requests and other inquiries.

Get A Quote

If you have a large request or a product question, please complete the short form below. Once received, one of our ducting product experts will respond to your request within 24 hours.