Woodworking Ducting

Wood dust and particles generated from cutting, sanding, shaping, and trim operations create serious health and safety hazards in woodworking environments. These fine contaminants are classified as known carcinogens and pose significant respiratory risks when inhaled. Wood dust also settles on equipment, work surfaces, and flooring, creating slip hazards and potential fire risks.

Sawdust from cutting operations, sanding particles from finishing work, wood dust from shaping and routing, and trim waste from building product manufacturing all require effective collection systems. When these contaminants go uncontrolled, they quickly accumulate throughout the workspace, putting workers at risk of overexposure.

Wood Dust Ducting Solutions

Dust collection systems for woodworking applications use ductwork installed directly on machinery to extract contaminants before they reach breathing zones. The captured airstream is filtered, and clean air is returned to the building or exhausted outside.

Nordfab® Quick-Fit® ducting provides the ideal solution for wood dust collection systems. The clamp-together design creates tight, leak-free seals that keep suction at the machines rather than losing efficiency through ductwork leaks. This modular system installs easily with simple duct clamps and gripple hangers, keeping installations secure yet adaptable.

When shop layouts change or machinery moves, QF® ducting disassembles and relocates in minutes—perfect for dynamic woodworking environments from one-person shops to large manufacturing facilities. The system accommodates everything from furniture manufacturing and cabinet making to building product production for windows and doors.

Tips for Optimal Performance:

• Keep duct runs as short as possible—longer runs increase static pressure and reduce performance

• Use larger diameter pipes for high-airflow collectors to lower static pressure

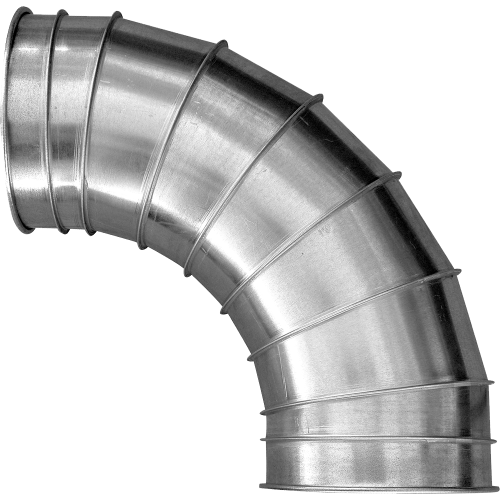

• Make turns gradual—sharp bends slow dust transport and can cause clogs

Nordfab® + Woodshop Case Study

Jay Tuttle, a hobbyist woodworker specializing in cabinets, tables, and chairs, needed a safe, efficient system to remove harmful wood dust from his workspace.

Our team designed a custom Quick-Fit® duct system, saving Jay both time and money on design and installation.

Request A Quote:

If you would like to request a quote for a ducting system, or to get more information about our products, please email us or use the form on our Contact Us page for support requests and other inquiries.

Get A Quote

If you have a large request or a product question, please complete the short form below. Once received, one of our ducting product experts will respond to your request within 24 hours.