Concrete Dust Ducting

Concrete dust generated from construction, demolition, handling, and processing of concrete, masonry, and rock materials creates serious health and safety hazards in construction and industrial environments. These crystalline silica particles are continuously produced during cutting, grinding, drilling, and demolition operations, requiring effective dust control systems to protect workers and maintain air quality.

Silica dust from concrete cutting and grinding operations, masonry particles from chipping and drilling processes, crystalline silica from abrasive blasting activities, concrete debris from demolition work, and fine particulates from sawing and sanding all pose significant respiratory and safety risks when airborne in construction sites and industrial facilities.

Exposure to these contaminants occurs in construction environments where employees work with abrasive blasting equipment, concrete cutting and grinding tools, demolition machinery, and masonry processing equipment. Concrete dust is associated with serious health effects, including silicosis and lung cancer, and these fine particles are easily dispersed throughout the respiratory tract. High concentrations of concrete dust in work areas create immediate safety and health risks for workers.

These contaminants accumulate on equipment and surfaces, reducing visibility and creating hazardous working conditions. The crystalline silica in concrete dust poses long-term health risks when particles reach the lungs, requiring specialized dust collection systems with high-efficiency filtration to prevent dangerous exposures.

Concrete Ducting Solutions

Industrial dust collection systems capture these contaminants using concrete dust ductwork mounted on cutting equipment, grinding tools, drilling machinery, and demolition equipment. The captured airstream moves contaminated air through high-efficiency filtration systems where it's cleaned and returned to the building or exhausted outside to meet strict air quality standards.

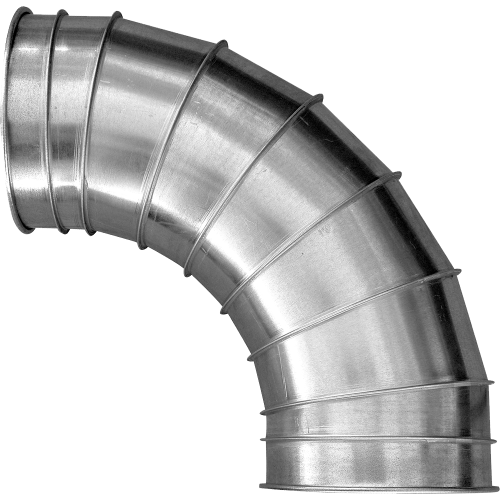

Nordfab® Quick-Fit® ducting provides solutions for concrete dust collection across construction sites, masonry operations, and industrial concrete processing facilities. Nordfab®'s modular design enables rapid deployment and reconfiguration as project needs change, whether moving between job sites or adapting to different equipment configurations.

Available in galvanized steel and stainless steel construction, Nordfab® QF® ducting is built to meet the demanding challenges that the construction and masonry industries face. The all-metal construction reduces the risks of dangerous static electricity buildup, and the smooth, rigid interior lessens static pressure loss even over long runs. Contact our team of specialists for a solution tailored to your specific concrete dust application.

Concrete Dust Duct Parts

Concrete dust collection requires all-metal ductwork components that eliminate static buildup and provide smooth interiors to effectively capture hazardous silica particles from cutting, grinding, and demolition applications.

Request A Quote:

If you would like to request a quote for a ducting system, or to get more information about our products, please email us or use the form on our Contact Us page for support requests and other inquiries.

Get A Quote

If you have a large request or a product question, please complete the short form below. Once received, one of our ducting product experts will respond to your request within 24 hours.