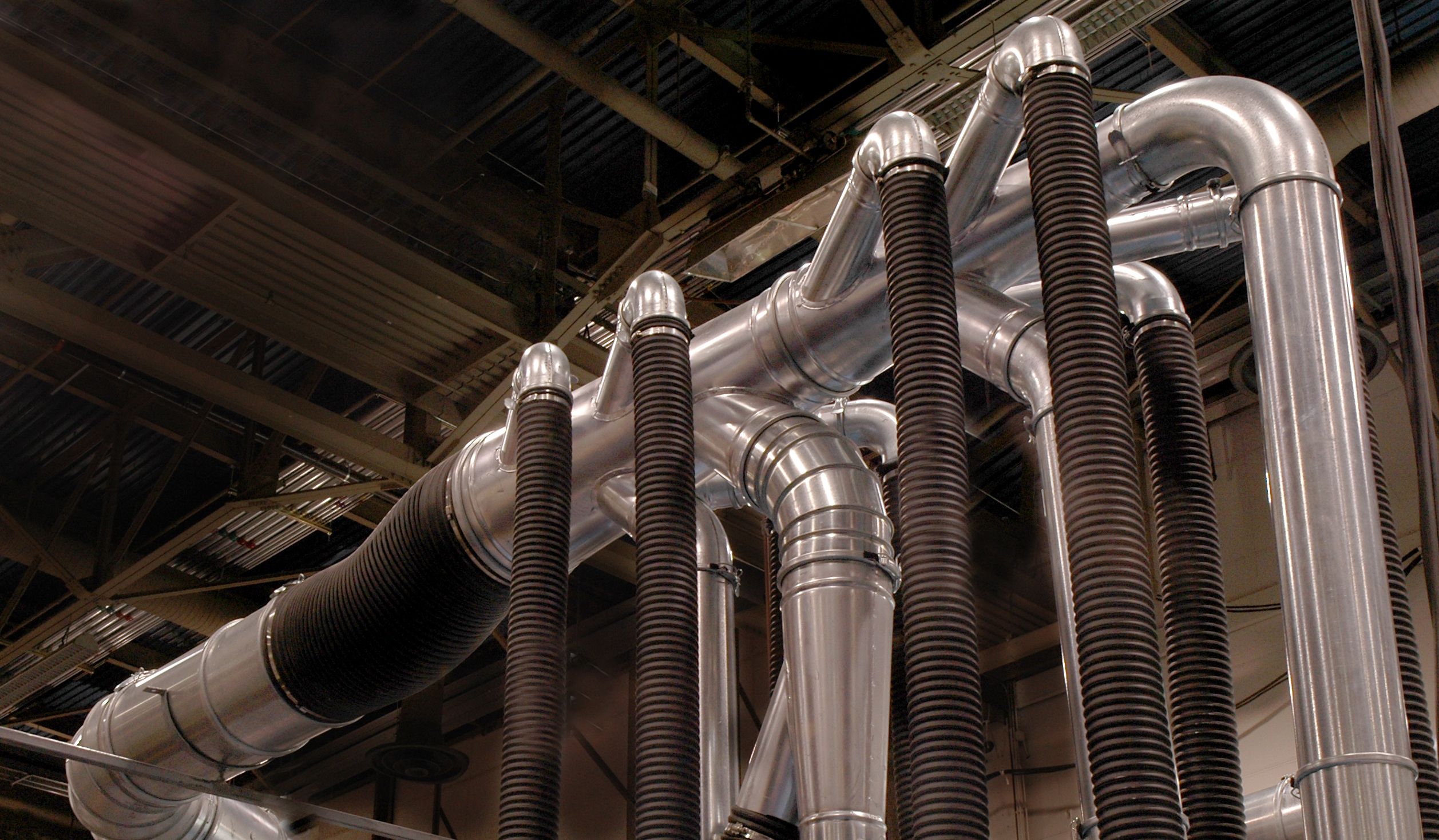

Galvanized Steel Ductwork

| Manufacturing Capabilities | |

|---|---|

| Materials: | Galvanized: ASTM A527 with a G90 rating i. Temp rating is 500° F with no breakdown of zinc - Zinc melting point is 740° F |

| Gauges: | 10ga - 22ga |

| Welds: | Spot weld & caulked, full weld upon request |

| Diameters: | 3" - 84" |

| Connections: | Rolled Lip, Flange, Raw (butt weld), Tri-Clamp, Flat Lip Clamp |

Galvanized ducting is one of the most cost-effective ways to protect metal compared to other steel coatings. The galvanizing process involves applying a zinc or alternative metal coating to a dense base black metal, providing strong anti-corrosion properties that shield it from rust and environmental elements.

WWhen ductwork material is galvanized, it gains direct protection against exposure, preventing oxidation and corrosion.

* Shop Nordfab® Galvanized Steel Parts Catalog *

In addition to withstanding harsh environments, galvanized duct is resistant to water and moisture, which can otherwise lead to corrosion. However, if the zinc coating is scratched deep enough to expose the steel beneath, corrosion may begin to develop.

Because Nordfab® Quick-Fit® galvanized pipes consist of resilient materials nearly all outdoor applications prefer them over other plastic pipes like PVC or ABS. Not only is galvanized ducting ideal for outside applications, they also excel in operations that produce wood, lead, and cement dust, vehicle and paint booth exhaust, welding fume, and are utilized to manage overall dust extraction.

Galvanized Duct Parts

Nordfab® manufacturers galvanized ductwork to provide commercial and industrial installers and designers a reliable, secure and effective way to apply and relocate ductwork. By implementing a Nordfab® Ducting system, industry experts no longer have to worry about caulking which saves them almost 50% of installation time.

Nordfab® galvanized duct products are laser, leak-tight welded systems that ensure ductwork is air tight. Galvanized ductwork by Nordfab® dispose sof areas where bugs can harbor, removes snagging areas that damage leak-free structures, and is adaptable to already installed duct systems.

Benefits of Using Galvanized Steel in Ductwork

✓ Heavy-duty coating: Galvanized steel duct has a coating that is made up of a special metallic structure to resist mechanical damage

✓ Cost efficient: Galvanized ductwork is the most cost-friendly and is standard for most applications because it lasts longer and requires less maintenance

✓ Long lasting: Galvanized coating is generally expected to last up to 50 years in most rural environments and 25+ in urban and coastal areas

✓ Total protection: The entire line of Nordfab® galvanized products is completely protected from corrosion, rust, water and moisture damage, even in inaccessible areas