Do I Need Galvanized Duct & Pipe?

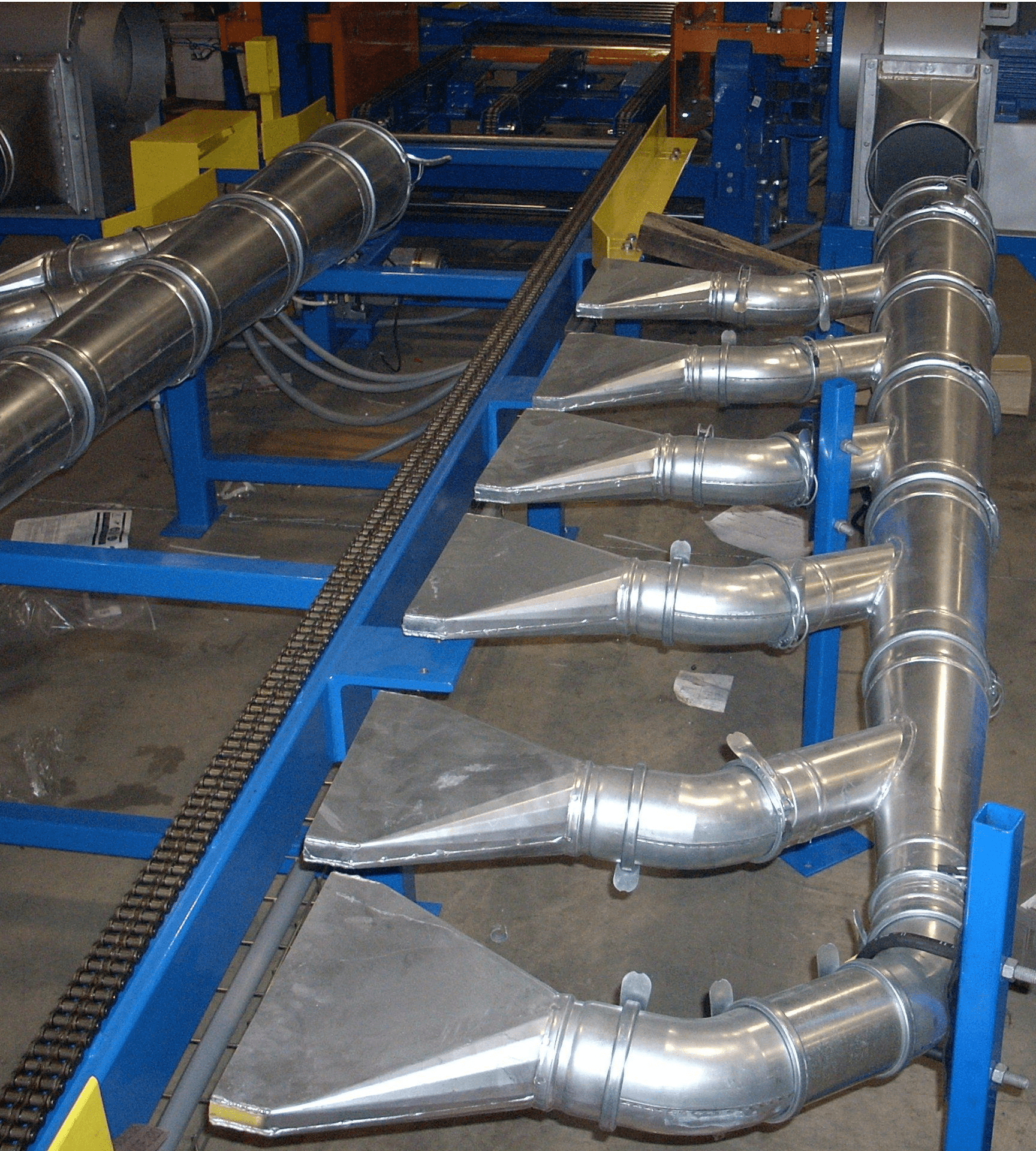

Galvanized ductwork has become the standard because it's the most affordable and widely used ducting material. Galvanized steel ducting is the toughest material to use but is excellent for abrasive applications such as transport systems.

Galvanized ductwork also boasts impressive durability and longevity. When properly installed and maintained, these systems can last 20 to 50 years or even longer in typical indoor applications. This exceptional lifespan is a testament to galvanized steel's robust nature and resistance to wear and tear.

Several factors contribute to its long-lasting performance:

✓ Resilience to Temp Changes: Galvanized steel handles normal temperature fluctuations well, maintaining its structural integrity over time.

✓ Humidity Resistance: While high humidity can potentially accelerate corrosion, galvanized ductwork generally performs well in varied environments.

✓ Air Quality Tolerance: Even in the presence of some airborne particles or chemicals, galvanized ductwork maintains its effectiveness.

✓ Installation Quality: Proper installation, including correct sealing and support, significantly enhances the system's durability.

✓ Maintenance: Regular inspections and maintenance can extend the life of galvanized steel ductwork.

✓ Galvanization Thickness: The protective zinc coating provides excellent corrosion resistance, with thicker coatings offering even longer protection.

Understanding these factors allows facility managers to maximize the lifespan of galvanized ductwork, ensuring long-term performance and value. This durability, combined with its versatility and cost-effectiveness, makes galvanized ducting an excellent choice for many applications.

Practical Applications and Limitations of Galvanized Duct Systems

Galvanized duct systems are not efficient in applications where resistance is needed from weather and corrosives because they're designed to be used indoors. Galvanized duct and fittings allow for a transition of different sizes and shapes that wind through rooms, hallways, and walls.

For example, using a tee separator will split airways into two different directions into a downstream branch network to respective rooms. These sections can also be constructed into different sizes to provide a larger circulation of air into one room rather than the other when air demands are specific for each area of the building.

| Applications | Pros | Cons |

|---|---|---|

| Indoor use only | Abbrasion protection | Corrodes more than other materials _ |

| Dry material (no moisture or condensation) | Most common option | |

| Reasonable temperature levels | Least expensive material __ |

Although aluminum and stainless steel can also be used for ductwork applications, galvanized duct systems are popular for their ability to be bent and cut to easily mold the system for an easier design.

These systems are also commonly wrapped with thermal fiberglass insulation to provide an improved method of limiting the amount of heat lost or gained by the system. Wrapping galvanized ductwork with insulation also inhibits the system from accumulating condensation while the air system keeps cooled air in a warm environment. This is another form of removing leaky air systems from dripping moisture into building rooms.

You may also like:

• 8 Reasons to Use Nordfab® Ducting

• Dust Collector Ducting Design

• Common Ducting Challenges and Solutions