Preventing Dust Collection Fires: A Closer Look at Nordfab's Spark Trap Technology

In industrial environments where dust collection is critical, fire prevention remains a top priority for facility managers and safety officers. The Nordfab In-line Spark Trap 2.0 represents a reliable complementary fire prevention solution for dust collection systems—combining simplicity, effectiveness, and economic value.

Effective, Budget-Friendly Safety Solution

When integrated into existing ductwork within dust collection systems, the Nordfab In-line Spark Trap 2.0 substantially minimizes fire hazards by intercepting and neutralizing sparks before they travel through the system to reach cyclones or collection chambers.

What makes this device work is an ingeniously simple concept—creating deliberate turbulence in the normally smooth airflow pattern. This disruption effectively cools and eliminates sparks during transit. The beauty of this approach lies in its simplicity:

• Zero mechanical components to maintain

• No electrical connections or power requirements

• Negligible impact on system pressure

• Doesn't create additional dust accumulation points

Engineering Behind the Innovation

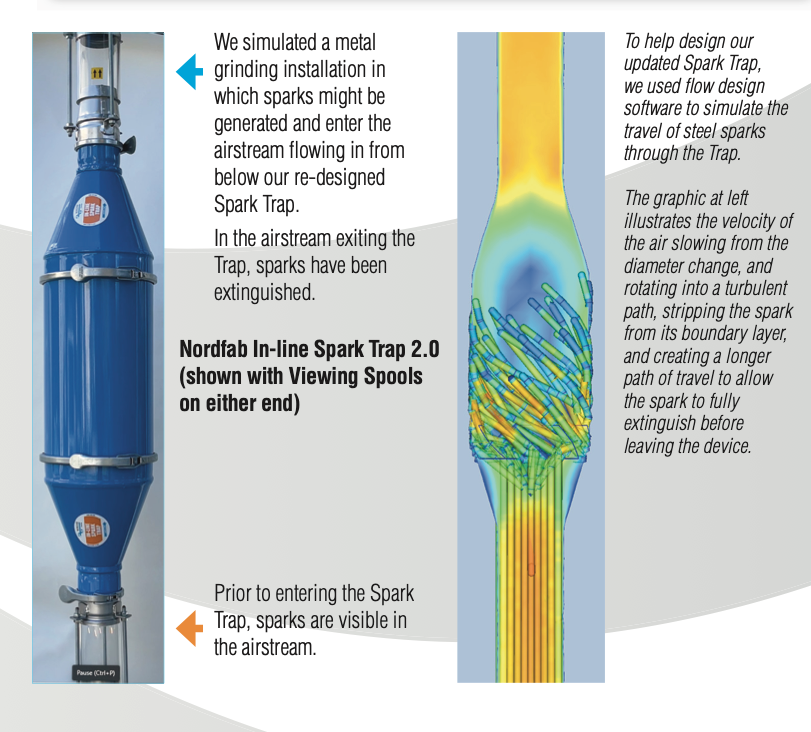

Nordfab used sophisticated flow design software to optimize the 2.0 version of their Spark Trap. The simulation data reveals exactly how the trap works:

1. As air enters the trap, its velocity slows due to the diameter change

2. The airflow rotates into a turbulent path

3. This turbulence strips sparks from their boundary layer

4. The elongated journey through the device gives sparks sufficient time to cool completely

To validate the design's effectiveness, engineers conducted virtual testing that replicated conditions found in typical metal grinding operations. These simulations tracked how sparks would behave when entering the system. The visualization confirms what theory predicted: sparks clearly visible in the intake airflow are entirely absent from the output stream after passing through the trap.

Quick, Easy Installation and Cleanout

One of the standout features of the Nordfab system is its Quick-Fit® clamp-together ducting, which eliminates the need for rivets, screws, or welding. This design significantly reduces the time required to install or replace ducting.

The In-line Spark Trap 2.0 can be:

• Quickly mounted into existing Quick-Fit ducting systems

• Integrated with other duct systems via flanged ends or with a Nordfab adapter

• Easily removed for routine cleanout

• Installed without requiring calibration or assistance from factory technicians

Improved Design Features

The 2.0 version features several important improvements:

• Improved pressure loss for better system efficiency

• Enhanced design based upon comprehensive flow design analysis

• Flexible installation options in either vertical or horizontal positions

• Snag-free construction reducing the risk of internal buildup

• Quick clamp disassembly for sizes up to 18 inches

• Durable powder-coated mild steel construction

Technical Specifications

The Nordfab In-line Spark Trap 2.0 is available in multiple sizes ranging from 4" to 24" diameter, with appropriate dimensions for each application. For optimal performance:

• Recommended velocity: 1500-3500 fpm (feet per minute), with 3000 fpm suggested for maximum performance

• Duct distance recommendation: At least ten diameters from cyclone/collector

• Available with Quick-Fit ends or as a Spark Trap AFL Assembly which includes two Angle Flange Adapters for flanged applications

• Each size option has been carefully designed with specific dimensions and weight considerations, with pressure loss data available for different velocity scenarios (3000 fpm, 4500 fpm, and 5500 fpm).

Important Safety Consideration

While the Nordfab In-line Spark Trap 2.0 significantly reduces fire risks, it's important to note that it complements rather than replaces comprehensive fire safety systems.

It's worth emphasizing that this device should be considered part of a comprehensive safety strategy rather than a standalone solution—it enhances but doesn't replace dedicated spark detection systems or explosion isolation mechanisms.

Key Benefits: Protection, Practicality, and ROI

Implementing the In-line Spark Trap offers facilities a straightforward yet effective way to enhance fire prevention measures. This investment typically yields multiple returns:

• Decreased financial impact from potential fire incidents

• Minimized production downtime and business interruptions

• Enhanced protection for personnel and equipment

For facilities managing dust collection systems—particularly in metal grinding, woodworking, and similar applications—the In-line Spark Trap 2.0 represents a practical approach to enhancing fire prevention measures. As Nordfab advises, system redundancy and complementary measures should be applied for comprehensive protection.

You may also like:

• Industries that Benefit Most from Nordfab®

• Key Components of Nordfab® Ducting Systems

• Everything to Know About Clamp Together Ducting